The Art of Enameling: How Jewelry Comes to Life in Color

In the world of fine jewelry, few techniques are as timeless—and as mesmerizing—as enameling. Dating back to ancient Egypt, enameling has been used for centuries to add vibrant color, depth, and meaning to jewelry. At Tempus Metals, we use hot glass enamel to create custom pieces that tell deeply personal stories, often incorporating ashes or sentimental symbolism.

But what exactly is enamel? And how is it applied to fine jewelry? Let us walk you through the process.

What Is Enamel?

Enamel is a type of powdered glass that’s fused to the surface of metal using high heat. Once fired, it creates a hard, glossy finish that can be smooth or textured, opaque or translucent, depending on the technique used. Unlike paint or resin, true enamel is glass—and that’s what gives it such enduring beauty and strength.

Step 1: Designing the Jewelry

Every enamel piece begins with a carefully considered design. Whether a client selects one of our signature styles or commissions a custom piece, we collaborate closely to create a memorial that feels deeply personal and meaningful. Together, we refine the layout, incorporate special details, and select the appropriate metal—typically 18k gold, chosen for its durability and compatibility with hot glass enameling. Once the design is finalized, we move into production, where the vision begins to take physical form.

Step 2: Preparing the Surface

Before enamel can be applied, the jewelry piece is cast, polished, and thoroughly cleaned. The surface must be free of oils and porosity. A texture is added to the small recessed areas in the metal to hold the enamel—this technique is known as champlevé, and it's one of the most common methods used in modern enamel jewelry.

Step 3: Applying the Enamel

Now the real magic begins. We sift and pack finely ground glass powder into the recessed areas of the metal. The enamel powder may appear pale or chalky at first, but don’t worry—it transforms during firing.

For multi-colored pieces, we work in layers. Each color must be fired separately to prevent blending or distortion. This makes the process time-consuming, but the results are worth it.

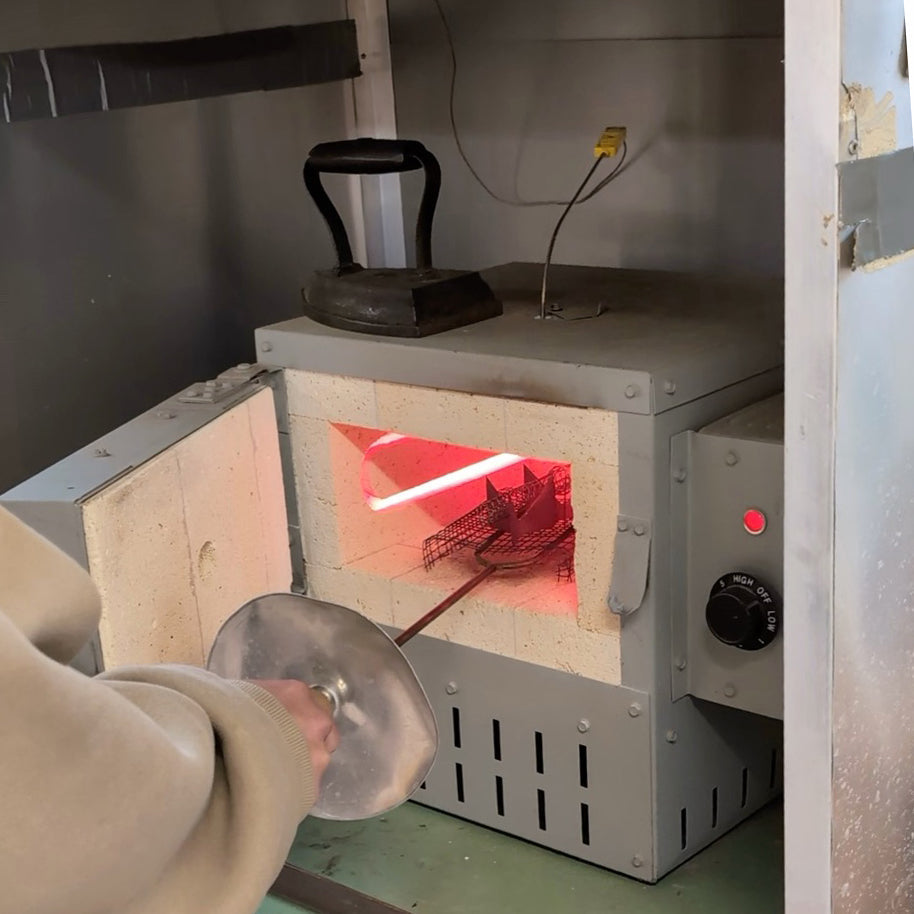

Step 4: Firing in the Kiln

The piece is then fired in a high-temperature kiln—typically between 1300°F to 1400°F. This process melts the glass powder, fusing it to the metal and creating a luminous, smooth finish.

We repeat this step several times to build up layers of enamel or achieve specific effects. Each firing takes skill and precision—too much heat or uneven temperatures can cause cracks, bubbling, or color distortion.

Step 5: Finishing Touches

After the final firing, the enamel is gently sanded and polished to create a flawless surface that flows seamlessly with the surrounding metal. After this stage, we set diamonds and apply finishing touches. The finished piece is not just jewelry—it’s a miniature work of art.

Why We Use Hot Glass Enamel

At Tempus Metals, we exclusively use hot glass enamel in most of our work. While some jewelers opt for cold enamel (a resin-based alternative), we prefer the durability, richness, and authenticity of true vitreous enamel. It’s more labor-intensive, but it produces heirloom-quality results that stand the test of time.

Interested in a custom enamel piece?

Reach out to us today—we’d love to help you design something truly personal.